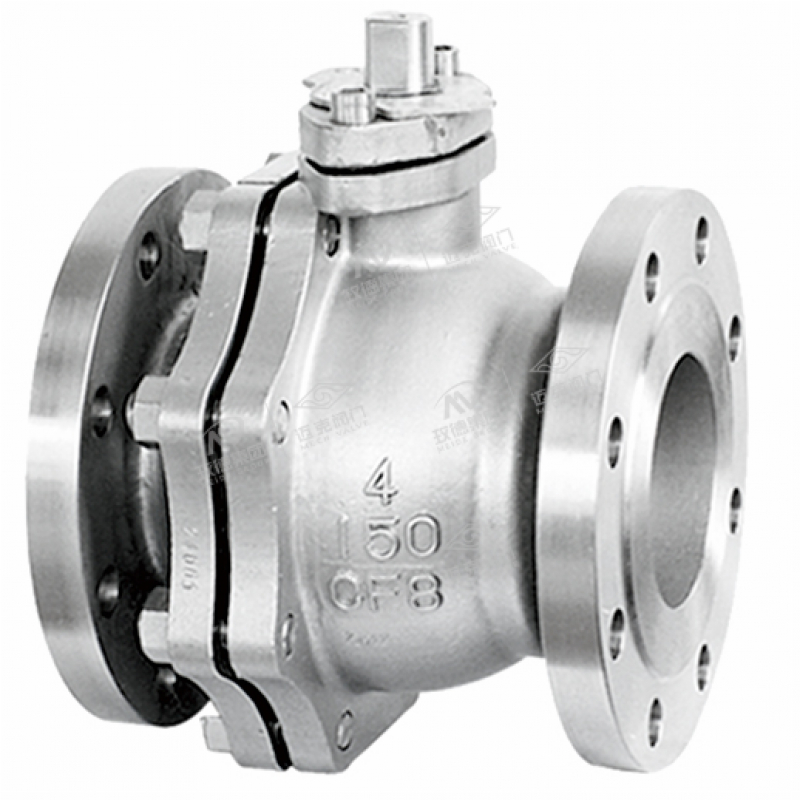

American Standard Floating Ball Valve

Product Overview:

Ball valve is a valve device widely used in the field of fluid control, and its core component is a ball with a through hole. By rotating the sphere 90 degrees, the through hole can be aligned or perpendicular to the pipe, allowing the fluid to be switched on and off and the flow rate regulated. The main advantages of ball valves include simple construction, excellent sealing performance, light operation and low flow resistance, making them indispensable and critical equipment in industries such as oil, gas, chemical and water treatment. According to the structural design, ball valves can be divided into floating ball valves and fixed ball valves: floating ball valves rely on medium pressure to achieve sealing, which is suitable for medium and low pressure scenarios; Fixed ball valves, on the other hand, are mechanically fixed to the ball and are suitable for high-pressure or large-diameter pipes. In addition, according to the connection method, the ball valve can also be divided into flanged type, threaded type and welded type to meet different installation needs. Ball valves are particularly suitable for high pressure, high temperature and corrosive media, especially when fast opening and closing or frequent operation are required. With advances in materials science and manufacturing technology, modern ball valves are improving in terms of corrosion resistance, sealing performance, and intelligence, enabling ball valves to meet more demanding industrial demands while improving system reliability and efficiency.

Specifications:

> size range: 1/2"~48" (DN15~DN1200)

> Pressure Rating: ASME150~2500LB(PN16-PN420)

> temperature range: -46°C-538°C

> connection methods: flange, welding, threading, etc

> main material: carbon steel, stainless steel, duplex steel, alloy steel, etc

> sealing surface hardening treatment: surfacing welding Stellite alloy and nickel-based alloy, spraying WC

> operation mode: manual, electric, pneumatic, hydraulic, pneumatic, electro-hydraulic, etc

Product Standards:

Design standard: API6D

Structure length: ASME B16.10

Connecting flange: ASMEB16.5

Test and Inspection: API598

Features:

1. The ball valve is suitable for pipelines under various working conditions such as petroleum and chemical industry with a nominal pressure of 1.6-42.0MPa (Class150~2500) and a working temperature of ≤538°C, and is used to cut off or connect the pipeline medium.

2. It has the lowest flow resistance, which can realize fast opening and closing, no impact when the valve is opened and closed quickly, fire-proof, anti-static, anti-fly-out safety structure, and sealing of the ball and valve seat when fully open and fully closed

The surface is isolated from the medium, so the medium passing through the valve at high speed will not cause the erosion of the sealing surface, and the ball valve channel is smooth and smooth, and it is not easy to deposit the medium, and the pipeline can pass through the ball.

3. According to different media and pressure, the sealing surface can be selected as soft seal and hard seal, and the structure can be used as floating ball, fixed ball, tee, cross, V ball, eccentric hemisphere, etc.

4. The ball body and seat sealing surface of the ball valve are made of cemented carbide material, which is corrosion-resistant, wear-resistant, high-temperature and high-pressure, and has a long service life.

5. The opening and closing of the ball valve only rotates at 90°, so it is easy to realize automatic control and long-distance control, and can be matchedVarious drive modes.

Related Products

Submitted successfully

We will contact you as soon as possible