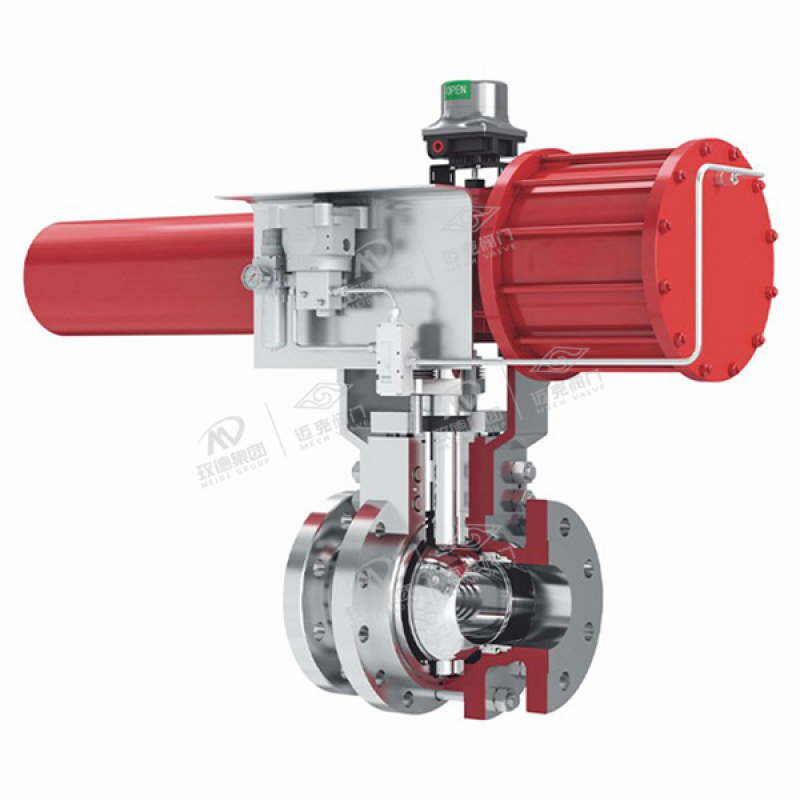

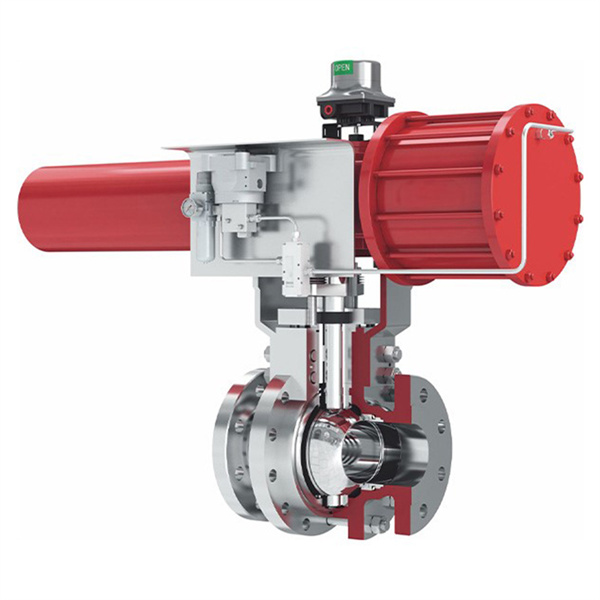

Slag locking valve

1. High-precision components, excellent dimensional consistency, and lower torque enable more economical and rapid opening and closing;

2. Ultrasonic flame spraying of tungsten carbide and chromium carbide, plasma spraying of nickel-based alloys, and laser cladding of stellite alloys meet the requirements of different working conditions and extend service life.

Product overview

The slag-locking ball valve is a special type of metal hard-seal ball valve used in specific operating conditions. Also known as a lock hopper valve, it is mainly used in coal chemical gasification furnaces for pressurized coal-water slurry gasification and dry coal powder fluidized bed pressurized gasification to control the slag discharge process.

Value advantage

1. High-precision components, excellent dimensional consistency, and lower torque enable more economical and rapid opening and closing;

2. Ultrasonic flame spraying of tungsten carbide and chromium carbide, plasma spraying of nickel-based alloys, and laser cladding of stellite alloys meet the requirements of different working conditions and extend service life.

Application scenarios

Slag-locking valves are widely used in industries such as coal chemical, polysilicon, petroleum, chemical, power, metallurgy, cement, sugar refining, and mining.

Technical parameters

Size range

NPS 2~16

Design standards:

API 608/ASME B16.34

Structural length standard:

ASME B16.10

Inspection requirements:

API 598

Work pressure:

CL600~CL2500

Temperature range:

-29℃~650℃

Main material: carbon steel, stainless steel, alloy steel and duplex steel, low temperature steel, nickel base, titanium alloy, etc.

Connection methods: RF, RTJ, BW

Transmission methods: manual, gear-driven, electric, pneumatic, and hydraulic.

Customer Challenges

1. Under low-pressure conditions, the metal sealing surfaces are difficult to fit fully, which can easily lead to leakage.

2. High opening and closing torque: The friction of the metal sealing surface is much greater than that of the soft seal, requiring greater operating force or higher-specification drive devices (such as higher-power actuators), which increases equipment investment and energy consumption.

3. High maintenance difficulty: Once the sealing surface is damaged, it requires professional grinding and repair, which is time-consuming and costly. Unlike soft seals, the sealing components cannot be directly replaced.

Related Products

Submitted successfully

We will contact you as soon as possible