Meide Group's domestic exhibitions are in full swing, and the China (Shanghai) International Fluid Machinery Exhibition is constantly exciting!

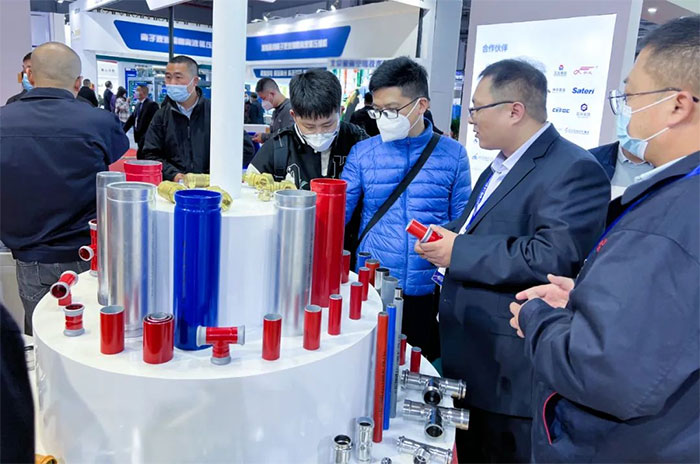

From March 7th to 10th, 2023, Meide Group and its subsidiary Jinan Mech Valve Technology Co., Ltd. participated in the 11th China (Shanghai) International Fluid Machinery Exhibition, marking the beginning of the 2023 domestic exhibition.

As the world's leading manufacturer and solution expert of fluid transportation products, Meide Group has displayed valves, pipes and fittings, steel pipes and other products to global customers. Huang Li, President of the China General Machinery Industry Association, visited Meide's booth to visit and provide guidance. Jinan Mech Valve Technology Co., Ltd. President Zhao Guizhi attended the reception. During the exhibition, the Meide team had in-depth exchanges with new and old customers and demonstrated to customers the unique advantages of Meide products in terms of quality, economy, safety, convenience, etc. While being widely praised, many cooperation intentions were reached.

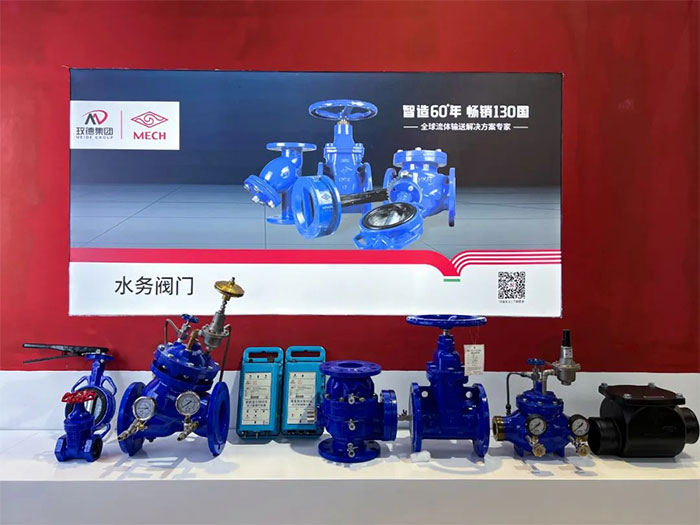

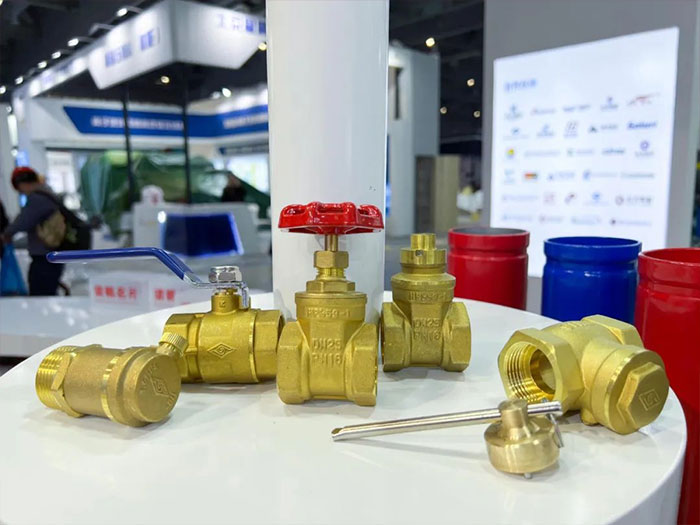

01Valve products

Mech valve products include gate valves, butterfly valves, ball valves, globe valves, check valves, regulating valves, safety valves, balance valves and filters made of ductile iron, carbon steel, copper alloy, stainless steel and other materials, which meet American standards, British standards, German, Japanese, Australian and other national standards have obtained 28 international certifications such as FM, UL, CRN, CSFM, CE, ROHS, NSF, VdS and LPCB, and are widely used in world landmark buildings and major livelihood projects, providing global fluid solutions. Conveying plays a key role in transmission and transfer.

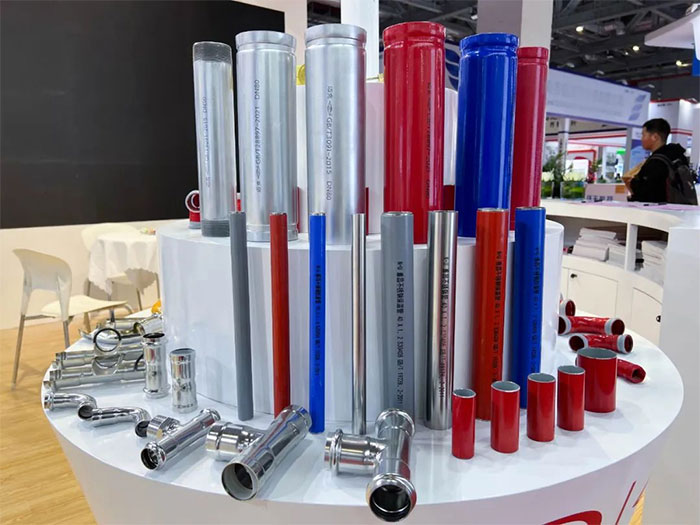

02 Pressure pipe fittings series products

Stainless steel compression fittings

Meade Yachang is the pioneer of domestic stainless steel double compression connection technology and the editor-in-chief of the national standard for stainless steel compression pipes and fittings. The stainless steel material has good corrosion resistance, excellent hygienic performance, and has the same lifespan as the building. Moreover, the double clamp has the characteristics of "five water leaks", that is, the interface does not leak when bending, strong vibration does not leak, the interface does not leak when crushed, and the interface rotates without leaking It is 360° waterproof and does not leak when the interface is pulled out. Using a Mahle solid solution furnace imported from Germany, pure hydrogen solid solution eliminates the impact of ammonia, water vapor and other impurities on stainless steel, making the surface anti-corrosion layer denser and doubling the anti-corrosion performance.

Carbon steel compression fittings

It is mainly used in the fields of gas and fire protection. The pipe fittings adopt double anti-corrosion technology, reducing carbon emissions by 210 tons per 100 tons of pipes. As a leading product of quick installation pipeline systems, it mainly has the following advantages:

1. Safe and reliable:

A. High pressure: the pressure is higher than 4.8MPa;

B. Anti-combustion: Stage 1, ambient temperature 760-870℃, water pressure 1.1MPa, under static water flow conditions, keep the pressure for 1 minute and then open the valve for 4 minutes; Stage 2: ambient temperature 260-370℃, water flow Conditions, lasting 5 minutes; Stage 3: Ambient temperature, water flow conditions, lasting 5 minutes; Stage 4: Sealing test 1.2MPa, no leakage;

C. Corrosion resistance: four layers of anti-corrosion for pipes, double layers of electro-galvanizing and electrophoretic paint for pipe fittings to increase the service life of the pipeline;

2. Fast installation: it only takes 7 seconds to press one place, which is more than three times the installation speed of traditional threaded connections;

3. Green and environmentally friendly: The pipe is light, beautiful, requires no painting, and no maintenance. The new coated pipe reduces carbon emissions by 310 tons per 100 tons;

4. Reduce costs: material costs are reduced by 5%-10%, and labor costs are reduced by 30%.

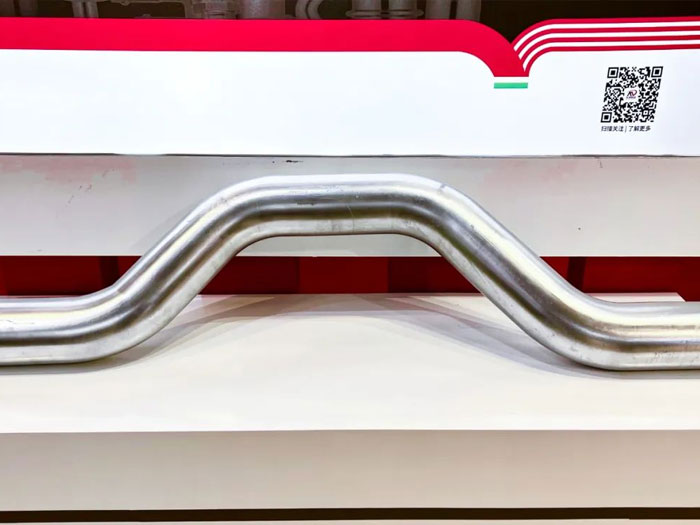

03 Galvanized bending products

Maike Pipe Industry independently developed a new product "Mech Brand" galvanized bending product to solve on-site construction problems. The bending product has 5 major advantages:

1. Material saving: It can replace the combined installation mode of a variety of products, including multiple 90-degree elbows, multiple pipe clamps and steel pipe joint products;

2. Fast installation: no need to assemble multiple components, only one installation is required;

3. Excellent quality: single steel pipe is formed, no connection points, reducing the risk of leakage and safer;

4. Easy maintenance: The cost of later maintenance (installation and replacement) is lower;

5. Safer: fewer connection points, small deformation, and high safety.

04 Plastic lined malleable steel pipe fittings

Mech brand plastic lined malleable steel pipe fittings have 5 outstanding advantages:

1. Excellent material: The material meets the requirements of GB/T9440 malleable iron castings KTH 350-10. It is produced using the DISA automatic molding line to ensure product consistency, uniform wall thickness, and reduce the risk of cracking of plastic-lined products.

2. High bonding strength: It is lined with thermoplastics with excellent chemical properties, which can ensure that it can withstand liquid pressure and mechanical impact like traditional galvanized pipes, and has sufficient strength and toughness.

3. Thread precision: Thread processing uses advanced automatic feeding tapping machines, using processing cutting tools, key cutting tools are imported, and is equipped with a complete set of thread detection tools and adopts standardized detection methods and frequencies.

4. Strong corrosion resistance: good corrosion resistance to non-oxidizing acids, dilute nitric acid, alkali and salt solutions, good corrosion resistance to organic solvents and normal temperature, slow scaling, and difficult to grow microorganisms; water is not directly In contact with metal, it will not rust or scale, the inner wall is smooth, and it has strong anti-corrosion ability.

5. High hygienic performance: it meets the requirements of CI/T 137 standard, the plastic lining material meets the drinking water requirements, and the performance indicators meet the standard requirements. It is suitable for transporting general corrosive liquid media, and is more suitable for transporting domestic water and drinking hot and cold water. It does not affect water quality during water transport and meets food-grade hygiene requirements.

05 grooved pipe fittings

Double-jointed process, spheroidization rate ≥90%; batch number management, quality traceability; rubber ring raw materials are from Dow, with glue content ≥40%; bolts are 100% magnetic particle inspected, and the surface coating is low-lead and environmentally friendly.

06 Straight seam steel pipe

Straight seam steel pipes are made of high-quality plates, well-known domestic steel mills, batch management, quality traceability; American Thermatool fully automatic welding machine, strong and stable welding, 100% online eddy current testing and water pressure testing; product series diversification: deep processing products are galvanized , plastic coating, spray painting, plastic lining and other processes, with in-factory prefabrication processing capabilities, one-stop solutions for groove pressing, threading, pipe cutting, and digital installation.